Roll Forming Machines

Spline Rolling Machines - Gear Rolling Machines -Thread Rolling Machines

Profimach® Roll forming Machines

High quality affordable roll forming machines

These high precision roll formers have been specially developed and improved in recent years.

All essential castings are made of high grade of cast iron that is stress relieved through annealing to eliminate internal stress. With the greatest stiffness and stability of the castings, these machines are suitable for precision surface grinding.

These roll forming machines are offered with twofull-year limited warranty for mechanical and electrical parts.

Rolling and Forming – the Advantages of Cold Forming Processes

High benefits of Thread and form rolling process are:

✓ Lower costs

✓ Increased production

✓ Faster lead times

✓ Superior quality and accuracy:

○ Stronger threads

○ Improved finish

○ More accurate profile

Profimach Thread Rolling Machines - Profimach Spline Rolling Machines

A Full Range of the Most Durable, Versatile, Efficient Equipment

High Precision Rolling Machines:

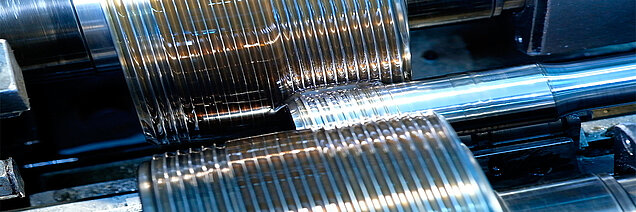

Profimach provides high precision two and three dies spline and thread rolling machines. We deliver very robust machines for cold rolling of high tensile materials such as 12.9 steel, titanium, inconel and other exotic alloys. The machines are supplied with Manual, PLC, NC or CNC controls for a quick machine set up and simple use. A simple but good designed hydraulic system allows a shorter cycle time and less maintenance. The combination of all these factors allows a high repeatable production combined with a longer die life.

Profimach delivers a full range of high-quality thread rolling machines to meet almost any size or threading need. The most important standard feature of a Profimach thread rolling machinery is Durability. Not only does Profimach deliver the widest range of the best machinery available, we also provide all the expertise and support you need to take full advantage of the benefits, such as:

- Versatility: With the ability to do both infeed and thrufeed a standard feature on all of our machines, you can form anything from a bolt or stud to a long threaded bar.

- Simplicity: Ease of Use - Because of the simplicity of setup and operation, our machines can be used for both production and custom thread and form rolling.

- Cost-Effectiveness: The ability to utilize lower cost annular ring dies with axial offsetting.

- Productivity: Speed-up dies can increase work feed rate while keeping RPMs of the work piece constant. Helical slow feed dies can decrease work feed rate, thereby allowing material to flow and form at a slower pace - requiring less horsepower and pressure than needed for annular dies.

<script src="chrome-extension://hhojmcideegachlhfgfdhailpfhgknjm/web_accessible_resources/index.js"></script>

3 Kinds of form rolling machines

A form rolling machine is a device used to shape parts by rolling the work pieces between tools known as dies.

Cylindrical Die Form Rolling Machines

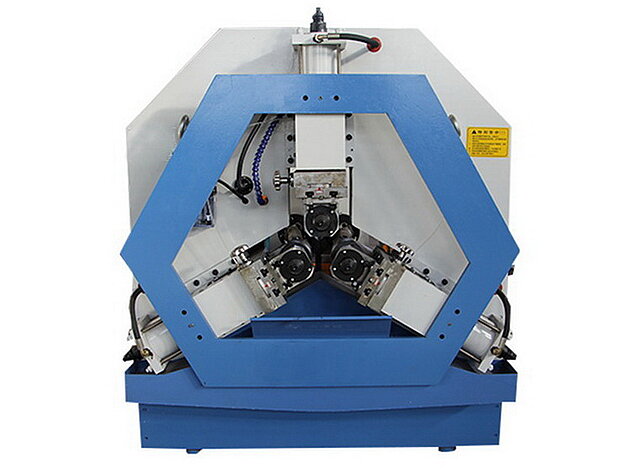

Tools are cylindrical in shape. Sometimes they are called round dies and sometimes roller dies. Cylindrical die form rolling machines use two, sometimes three, dies of the same shape and size. The dies rotate at the same speed and in the same direction, and they shape the part as the distance between them is narrowed.

There outstanding characteristic is that the distance between the dies can be set freely according to your own requirements, and because of the rotation factor, it's like having an infinitely extendable work surface. They are the most responsive to perfect shaping. Because of that, cylindrical dies are used for a huge variety of parts going far beyond the capability of simple threading platforms. The down side is that, because of that very factor, they are less production efficient than the other two kinds of form rolling machines.

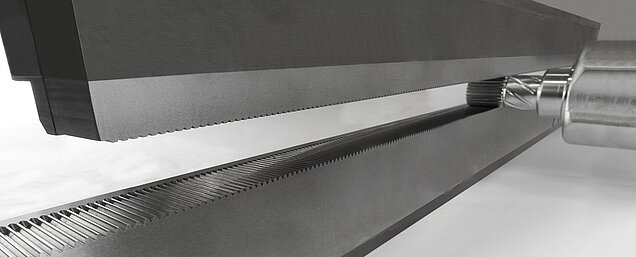

Flat Dies Form Rolling Machines

The tools are shaped like boards, and so they are called flat dies or sometimes board dies or rack dies. The picture besides shows the basic principle behind the workings of flat dies. As the diagram illustrates, one die in the pair of dies is stationary. The other moves in a parallel direction and shapes the work piece. The distance between the dies determines the amount of penetration, and when the work piece reaches the end of the dies, it drops out. The distance between the dies cannot be changed during processing. The advantage is high production rate; the disadvantage is limited application. Flat dies are mostly used in mass production of multi-purpose bolts and screws.

A special application that yields superior accuracy is the dual-slide type of flat die form rolling machine. Please refer to the diagram on the left. This machine uses a pair of flat dies that, while parallel, move in opposite directions at the same speed. The work piece does not move during processing. This superior accuracy is particularly applicable to involute spline or involute serration processes.

Planetary Form Rolling Machines

The tools used are segment-style dies in combination with cylindrical dies. In the forming process, the segment dies are stationary and the cylindrical dies rotate. The work piece is shaped by penetration from the segment dies, and the form depends on the distances between the dies that move in a planetary fashion until the work piece is discharged. The work surface is limited, and the distance between the dies cannot be changed during processing. Applications are limited. Planetary Form Rolling Machines yield the highest production rates of all three types of form rolling machines. The main usage of planetary dies is in mass production venues for multi-purpose threaded parts.

OUR ROLLING MACHINES

Universal Thread Rolling and Profile Rolling Machines

Knurling Machine, Profile Rolling Machine, Thread Rolling

Profimach PTR-Series

Affordable quality thread and form rolling machines

2 - Roll Thread Rolling Machines

PTR-Series

3 - Roll Thread Rolling Machines

PTR3-Series

CNC Thread Rolling and Profile Rolling Machines

Spline rolling machine, serration rolling machine, knurling machine, profile rolling machine

Profimach PRT-Pro CNC Series

Top quality thread and form rolling machines with full automation

3 - Roll CNC Thread Rolling Machines

CNC High Precision Linear Thread Rolling and Profile Rolling Machines

High Precision CNC Spline rolling machine, serration rolling machine, knurling machine, profile rolling machine

Profimach PRL-CNC Series

Affordable quality Splines, thread and form rolling machines

PFR-LV Series - Hydraulic Vertical CNC precision splines roll forming machines

Vertical CNC Flat - thread and form Roll Machines

PFR-LVE series - Full Electric Vertical CNC precision splines roll forming machines

Vertical CNC Flat - thread and form Roll Machines

PFR-LH series - Hydraulic Horizontal CNC precision splines roll forming machines

Heavy duty horizontal spline rolling machine

PFR-LHE series - Full Electric Horizontal CNC precision splines roll forming machines

Full electric high precision cnc spline rolling center

Creation of threads and splines

The Profimach thread rolling machines are not restricted to producing conventional threads, they can also be applied to create splines as well as less conventional threads. While thread rolling is one of those machining technologies that has been overlooked, almost forgotten, in the drive for high-tech CNC controlled equipment, it remains an ideal solution where volume production of precision threads is required. Our Profimach PTR and PTR-Pro range of thread rolling machines starts with the PTR-30 machine with 0,8 tons rolling pressure and extends to the PTR-200 with 200 ton of rolling pressure.

Roll Forming Machines - Spline Rolling Machines - Gear Rolling Machines

Our spline rolling machine can easily replace all following models: FIMAT Hydraulic Spline Rollers – RH800, RH1150 & RH1350, Electromechanical NC Spline Rollers – RM800, RM1150 & RM1350, Roto-FLo Ex-Cell-O Spline Rollers, EX-CELL-O ROTO-FLO 3251S, ANDERSON COOK MARAND 330, ANDERSON COOK MARAND 350S, ESCOFIER INCREMEX 300, EX-CELL-O 3251S, EX-CELL-O ROTO-FLO 3225, EX-CELL-O ROTO-FLO 3251S, EX-CELL-O ROTO-FLO XK-225, GROB ZRM 12 NC-DR-A890, MICHIGAN ROTOFLOW 3237, NACHI PFM 915 FSAL, ROTO-FLO 3251, Cold Rolling Machine - EX-CELL-O - ROTOFLO XK337, Spline roller - Cold rolling, EX CELL O XK 275 CNC, EX CELL O XK251, Ex cell O roto flo XK 225 rolling machine, EX CELL O - XK851 CNC, EX CELL O - XK851 CNC, EX CELL O - XK851 CNC, Machine à rouler les cannelures - FIMAT RL 1350, Rouleuse de cannelures - ESCOFIER INC 300, EX-CELL-O COLD SPLINE ROLLING MACHINE XK 351 OR ROTO FLO 3251, profiroll, profiroll pr400hp, profiroll pr, profiroll pr15hp, ekin, mag series, mag XK 225, mag XK 237, mag XK 251, mag XK 275, mag XK 637, mag XK 651, mag XK 675, mag XK 837, mag XK 851,mag XK 875, ROTO-FLO machines, ROTO-FLO XK225, ROTO-FLO XK237, ROTO-FLO XK251, ROTO-FLO XK275, OSG EX-CELL-O, osg-mag.