Profimach® Drehmaschinen

Hochwertige, erschwingliche Drehmaschine

Diese hochpräzisen Drehmaschinen wurden in den letzten Jahren speziell entwickelt und verbessert.

Alle wesentlichen Gussteile bestehen aus hochwertigem Gusseisen, das durch Tempern entlastet wird, um innere Spannungen zu beseitigen. Mit der größten Steifigkeit und Stabilität der Gussteile eignen sich diese Maschinen zum Präzisionsdrehen.

Diese Drehmaschinen werden mit einer zweijährigen Garantie auf mechanische und elektrische Teile angeboten.

Profimach Turning Lathes

Conventional and CNC turning lathes

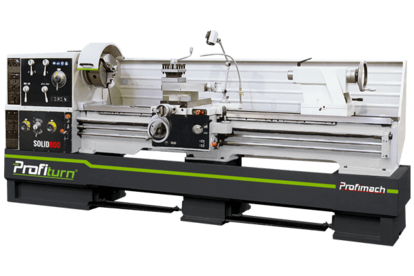

Conventional Turning Lathes

Conventional Turning Machines With 2 Bed Guideways

Conventional lathes designed for the highly efficient machining of workpieces in unit and serial production.

The rigid single piece double bridge casted bed construction, the high motor power, the wide range of spindle speeds with constant surface speed control and high top cutting speeds allow to perform the machining of almost all different materials.

Conventional turning lathes with Constant Surface speed

Servo Motor drive : ECO - One piece cast iron bed - Most rigid lathe in it's class

Profimach Solid PT-025 Series

Conventional Turning lathe with Constant surface speed - 420

Profimach Solid PT-030 Series

Conventional Turning lathe with Constant surface speed - 460

Profimach Solid PT-035 Series

Conventional Turning lathe with Constant surface speed - 560

Profimach Solid PT-040 Series

Conventional Turning lathe with Constant surface speed - 660

Profimach Solid PT-050 Series

Conventional Turning lathe with Constant surface speed - 800

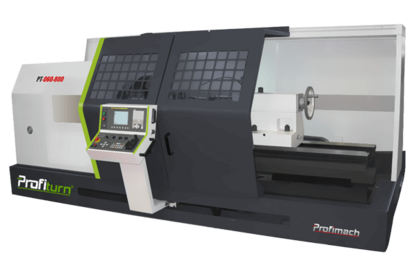

CNC Turning Lathes

CNC Turning Machines With 2 Bed Guideways

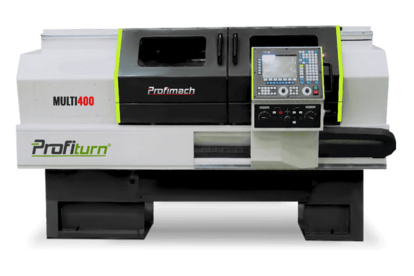

>> CNC Teach-in Turning Lathes

CNC Teach-in Turning Machines Overview

Profimach Teach-in Range

PT-30 CNC Multi Series

Profimach Teach-in Range

PT-040 Multi CNC

Profimach Teach-in Range

PT56-CNC Multi 800 Series

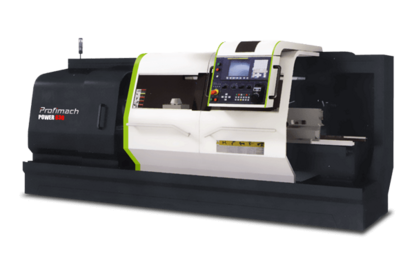

>> CNC Flat Bed Turning Lathes

CNC Flat Bed Turning Machines Overview

Profimach Power-Dual Saddle Range

PT-055DS CNC

Profimach Strong Range

PT60 - Series

profimach Captain Range

PT76 Series

Profimach Giant Range

PT 100 CNC Series

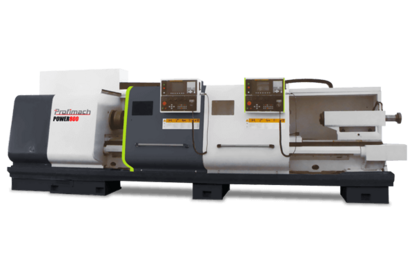

CNC Turning Lathes

CNC Turning Machines With 3 Bed Guideways

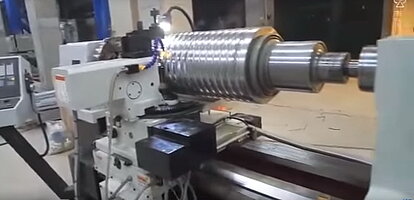

>>Notching & Marking & Crescent Grooves Milling TURNING MACHINE - CNC Tungsten carbide mill rolls ring lathes

NOTCHING & MARKING TURNING MACHINE and CNC Roller Crescent Grooves Miller lathe for CNC MILL-ROLLS and MILL-RINGS

Special turning machines for CNC MILL-ROLLS and MILL-RINGS

NOTCHING & MARKING TURNING MACHINE

CNC Turning Lathes

CNC Turning Machines With 4 or more Bed Guideways

General characteristics 4 guideways lathes

These machines are designed for medium-heavy duty tasks (turbine shafts, hydraulic cylinders, wind turbine masts and so on). Profimach CNC multi guideways lathes are really multitask centres, suited for high performed turning, boring, milling and grinding operations. The machine’s ergonomic feature allows the operator a good visibility throughout the various stages of machining, as well as eases of clamping, and check the product once it is finished. Steady rest must never be replaced during the full operation. Long shafts finished in one single set-up with only one clamping.

>>CNC Shaft Turning Lathe: PROFITURN SHAFT MASTER PRO Series - CNC Long Shaft Turning Lathe

PROFITURN SHAFT MASTER PRO Series - CNC Long Shaft Turning Lathe: PTRS-CNC Series TURNING MACHINE

Special turning machines for long shaft material

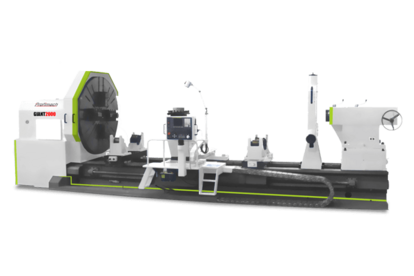

>>CNC Roll Turning Lathe: PTR-CNC Series TURNING MACHINE - CNC mill rolls lathes - CNC Long Shaft Turning Lathe

CNC Roll turning lathe

Full roll turning in a single set-up

The CNC Roll turning Lathe is the ultimate replacement solution for Manual Lathes used by Steel Plants in the Roll Shop for Roll machining and pass cutting. Available in various Models, the CNC roll turning lathes drive a huge improvement in productivity, reduce the need for labor, eliminate manual errors and reduce the space required for turning operation in machining the Rolls. The CNC Roll turning lathes from Profimach provide an economical solution to improve the quality of end product, productivity of the manufacturing process and thus adds to your profitability.

CNC Roll Turning Lathe: CNC ROLL MASTER PRO - CNC Series TURNING MACHINE - CNC mill rolls lathes - CNC ROLL Turning Machine

Special turning machines for CNC MILL-ROLLS and MILL-RINGS

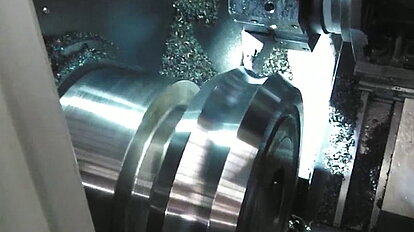

>>CNC Tungsten carbide mill rolls lathe - CNC Tungsten carbide mill ring lathes: PTRR-CNC Series T

CNC Tungsten carbide mill rolls lathe - CNC Tungsten carbide mill ring lathes - CNC lathe for CNC MILL-ROLLS and MILL-RINGS : PTRR-CNC Series T

Special turning machines for CNC MILL-ROLLS and MILL-RINGS

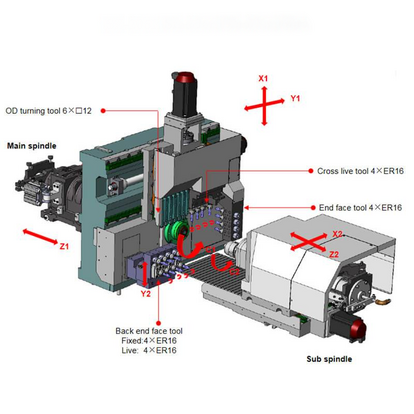

CNC Swiss Type Turning Lathes

CNC moving headstock Turning Machines for high precision complex turned and milled parts

>> CNC Swiss type Turning Lathes

Swisstek - III-th Generation Affordable high tech Swiss type complex turning cells.

CNC Swiss type Turning lathe overview

Swisstek - III-th Generation

Robotturn SwissTek A4 Series

X-Y-Z-C Axis with driven tools