FULL AUTOMATIC Folding and Bending with the Profimach Multilateral bending-Center makes your dreams come true!

The Profimach Multibend-Center panel bender is available in working lengths of 1000mm, 1500mm, 2000mm, 2500mm

Automatic Panel Bending Machine

More affordable than you think

In recent years, in the field of sheet metal processing, the application of automated processing technology has gradually become popular. The core technology of sheet metal processing automation lies in the automation of sheet metal bending. In the traditional bending method, when processing large-size and heavier parts, usually multiple operators are required to complete it, which is labor-intensive and the working environment is harsh. Therefore, fully automatic bending centers came into being and gradually began to replace manual bending.

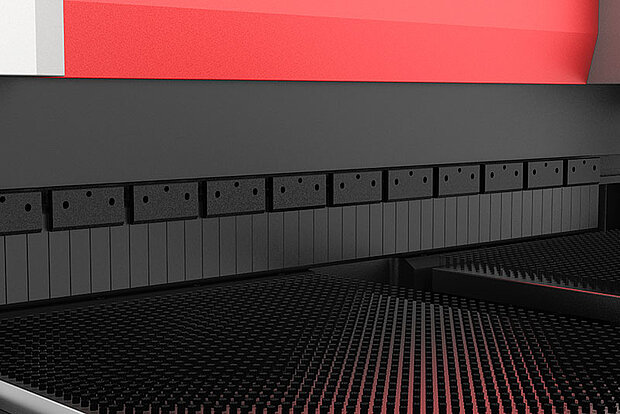

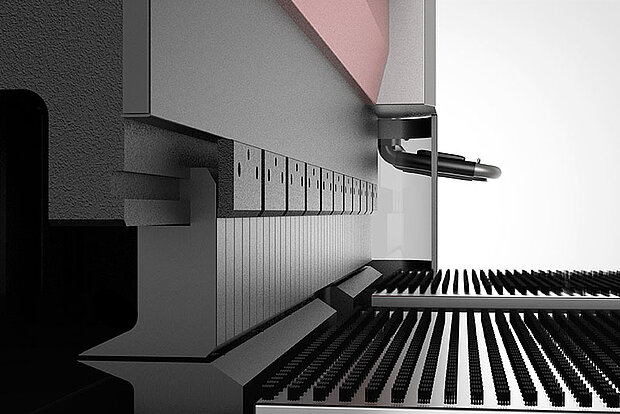

The automatic panel bender is an automatic equipment for processing thin metal plates below 3mm. Its structure mainly includes a tool holder, worktable, a clamping feeding device and a CNC operating table. The worktable is composed of a base and a clamping piece feeding structure. The workpiece is positioned and clamped on the worktable and delivered to the processing position through the feeding mechanism, and the bending tool is driven by the tool holder to process the workpiece.

Automatic Panel Bender

If you want to bend precision parts, fully automatically, at high speeds, in high quantity, regardless of batch-size, with the highest levels of flexibility and total repeatability, welcome to the next level of metal fabrication.

Although the manufacturing and accuracy of sheet metal equipment bending machines have been greatly improved than in the past, there is still a big gap between the "Road to Industry 4.0" and "Intelligent Manufacturing". "Personalized customization, service-oriented extension, and networked collaboration" also require joint innovation and development in the subdivision of sheet metal equipment manufacturing and the demand side. This innovative development, promotion and application is another increase and liberation of productivity.

The traditional bending of the sheet metal industry needs to solve the following problems:

- Manufacturing problems: can not achieve multiple varieties, small batches, and fast switching;

- The problem of low precision of parts: low precision of high-precision workpieces in the sheet metal industry. Unstable quality;

- The problem of difficult employment for enterprises: the shortage of sheet metal bending operators and the high labor intensity of workers;

- Comprehensive problems: personnel costs, safety hazards, process layout, management and operation.

The above problems can be solved by selecting a set of intelligent manipulator bending unit: including CNC bending machine, manipulator and guide rail, supporting feeding station, magnetic sheet separation device, centering positioning table, sheet turning mechanism, upper Material gripper, finished product stacking, offline programming software, parametric programming software and secondary development related bending software and extended services.

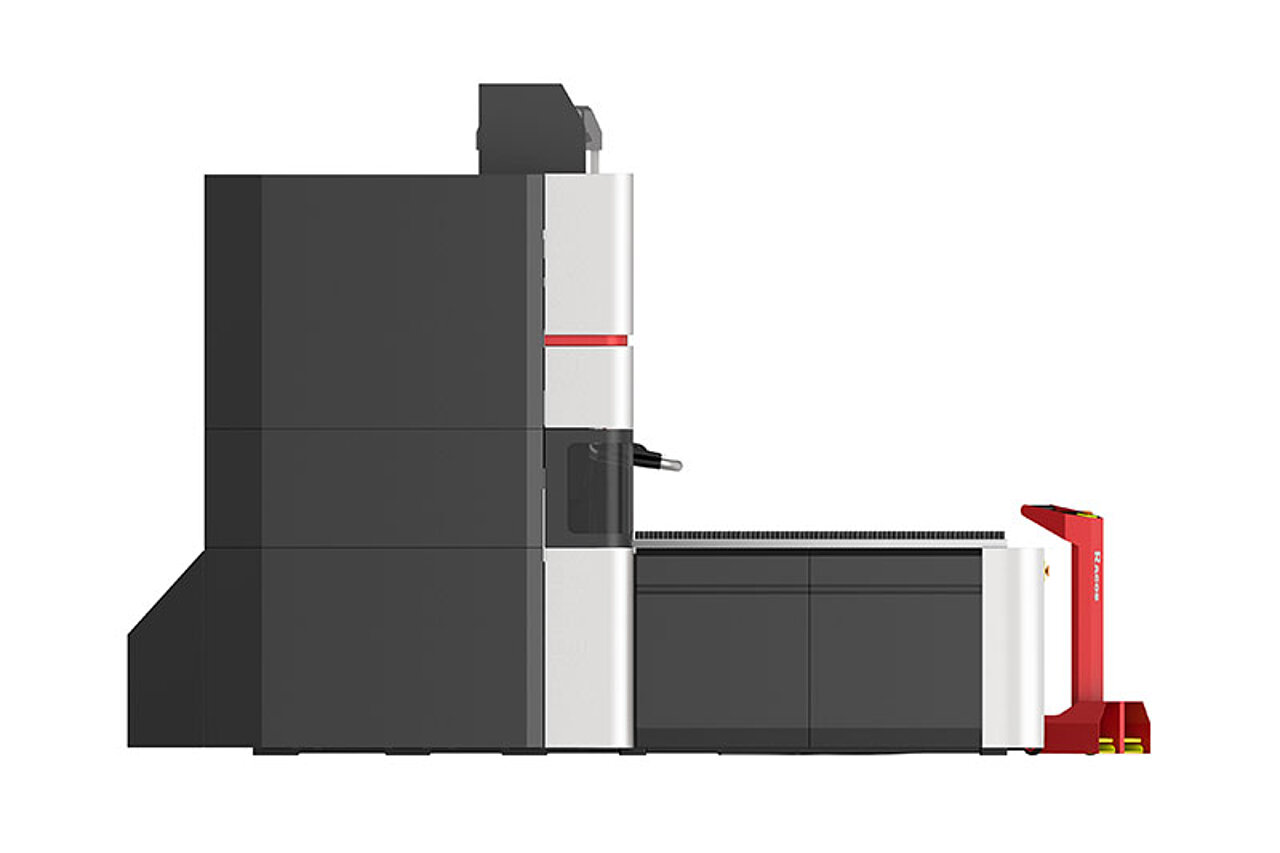

Profimach newest PBC 1000/1500/20002500 panel bending series is a new generation of full automatic panel bending center.

It is a benchmark product that the sheet metal manufacturing industry has stepped into automatic production.

- Saving the human resources.

- the bending speed is 3 times that of the traditional bending machine, reaching 0.5s/bend.

- Full servo control can keep the product precision within 3s of an angle.

- able to run 50.000 bends/day

Our fully automatic bending center can achieve high-efficiency bending productivity.

Fully Automatic Panel Bender

Up to 50.000 bends per day!!!

PBC-1000

1.0 m automatic folding and Bending

PBC/PBCV-1500

1.5 m folding and Bending with or without vertical clamping

PBCV-2000

2 m folding and Bending with vertical clamping

PBCV-2500

2,5 m folding and Bending with vertical clamping

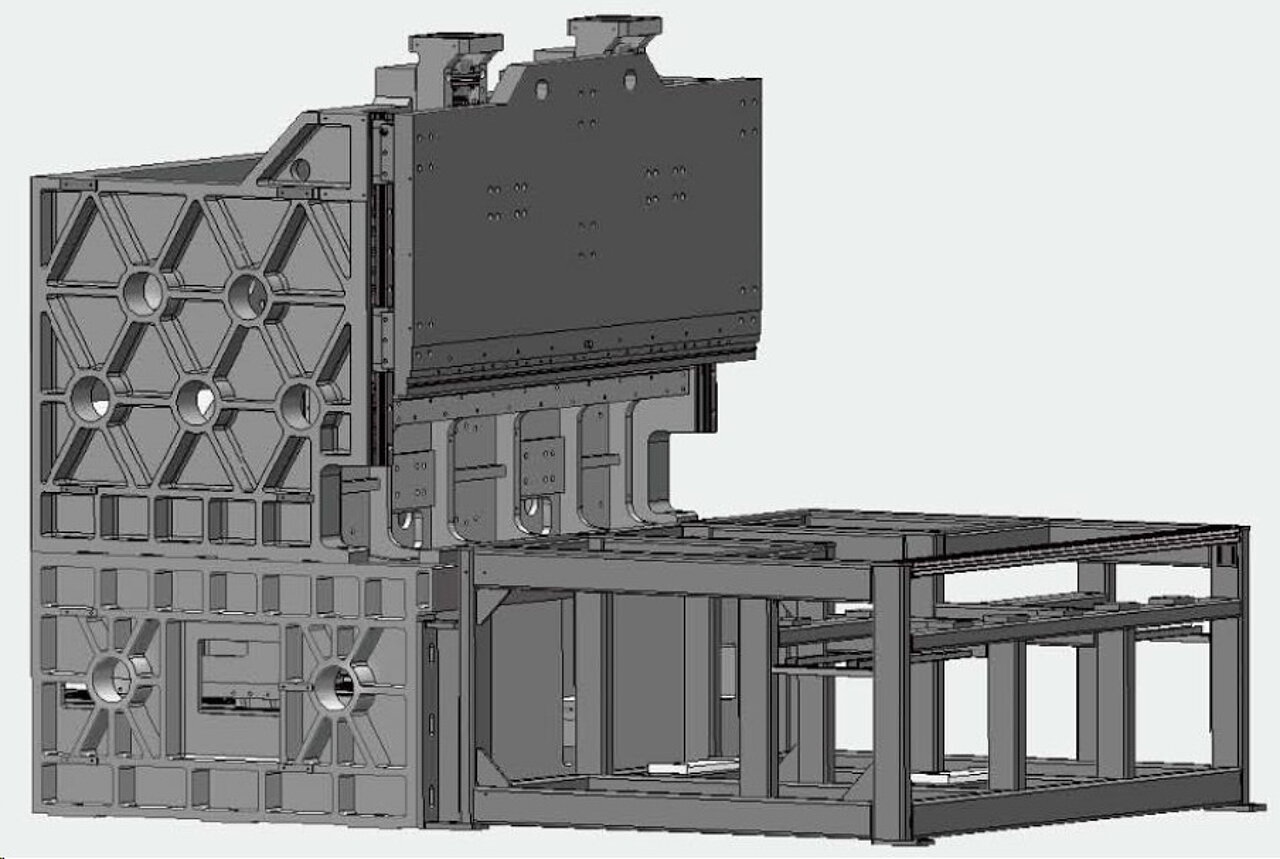

Rigidity and Precision are guaranteed by a full casted highly ribbed Bed structure

Precision, repetitivity and speed by rigid a Casted Frame

Servo electrical fully-automatic panel bending machine

The intelligent CNC automatic panel bending machine/press brake machine is an equipment for processing thin plates. Its structure mainly includes a tool holder, worktable, aclamping feeding device and a CNC operating table. The worktable is composed of a base and a clamping piece feeding structure. The workpiece is positioned and clamped on the worktable and delivered to the processing position through the feeding mechanism, and the bending tool is driven by the tool holder to process the workpiece.

Technical Parameters and Specification

| No. | Model | Unit | PBC-1000 | PBC-1500 /PBCV-1500 | PBCV-2000 | PBCV-2500 |

| 1 | Bending Length | mm | 1000 | 1500 | 2000 | 2500 |

| 2 | Plate Length | mm | 1100 | 1600 | 2100 | |

| 3 | Plate Width | mm | 1000 | 1250 | 1250 | |

| 4 | Bending Height | mm | 175/320 | 175/320 | 175/320 | 175 |

| 5 | Min Forming Size(Four sides) | mm | 320*200 | 350*180 | ||

| 6 | Min Forming Size(One side) | mm | 200 | |||

| 7 | Min Radius | mm | 1,2 | |||

| 8 | Bending Speed | s | 0.5/ Bend | |||

| 9 | Opening Height | mm | 180 | |||

| 10 | Angle | ° | 0-180° | |||

| 11 | Material Thickness | mm | "aluminum:2.0 carbon steel :1.5 | |||

| stainless steel:1.2" | ||||||

| 12 | Operating System | OS | Win7+OS | |||

| 13 | Axis | axis | regular:11 Optional :12/13 | |||

| 14 | Machine Dimension | |||||

| Length | mm | 2900 | 3370 | 4480 | 5280 | |

| Width mm | 1390 | 1890 | 2390 | 2900 | ||

| Height mm | 2600 | 2650 | 2700 | 2700 | ||

| 15 | Machine Weight | kg | 6920 | 8480 | 10640 | 14200 |

The Limitations of Traditional Sheet Bending Machine

1. High Labor Cost

In the traditional bending method, at least three auxiliary workers and one skilled worker are required to bend large galvanized sheets with a thickness of 1.2mm. For the bending of small plates, a skilled worker must rest for 20 minutes, and the accuracy of each bending is different. At the same time, the tacit understanding of the operators is insufficient, which is very easy to cause work injuries.

2. Poor Product Consistency

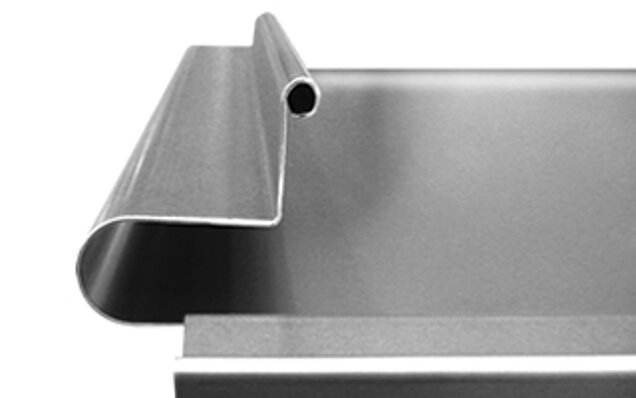

In traditional bending methods, for special processes such as arc processing, on the one hand, in the actual bending process, limited by the experience level of the bending workers, the error of arc bending is relatively large. On the other hand, the consistency of each bent sample is poor, which brings difficulties to later welding.

3. Low Efficiency

In the traditional bending method, the bending machine needs to prepare different bending molds according to different bending angles such as right angles, acute angles, arcs, etc. Workers need to frequently replace molds during actual operation, resulting in low work efficiency. At the same time, in the bending process, due to the direct contact bending, the damage to the abrasive tool is relatively large. Once the mold is damaged, the bending accuracy will be seriously reduced.

The Advantages of Automatic Panel Bending Center

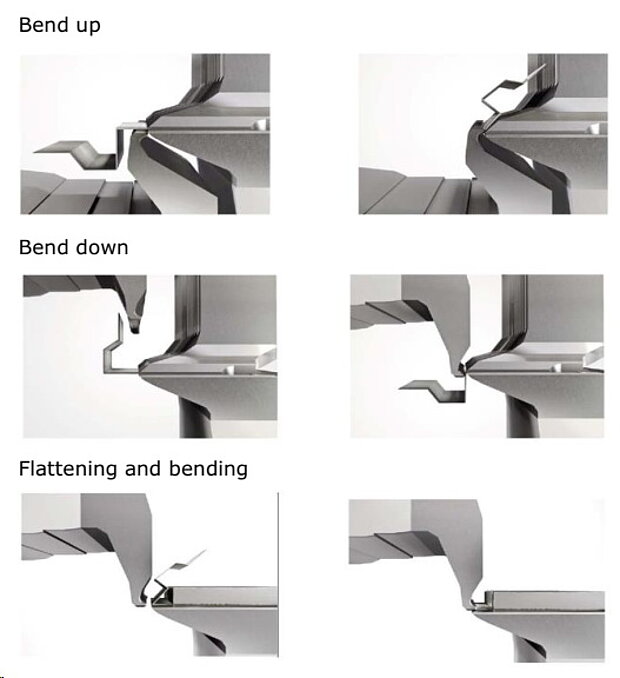

The fully automatic panel bending center independently developed by profimach will change the traditional bending method. It has the advantages of high precision, high efficiency, low cost, and high safety..

1. High Accuracy of Automatic Sheet Bending Machine

On the one hand, the automatic sheet bending machine adopts a servo clamping method to ensure the stability of feeding and improve the processing accuracy of the product. On the other hand, unlike the previous staff holding the sheet to bend, automatic sheet bending machine uses a mechanical arm to bend the sheet without error, thus ensuring the quality of batch processed products.

2.High Efficiency of Automatic Metal Sheet Bending Machine

In the manual bending process, workers need to lift large plates throughout the entire process. Once the operations are not synchronized, errors will occur, resulting in low efficiency. However, the automatic bending center does not need to manually lift the plate, avoiding the error caused by manual operation asynchronously, and improving the production efficiency. At the same time, the fully automatic bending center is equipped with universal molds, which eliminates the need to frequently replace upper and lower molds during the bending process, saving a lot of manpower and improving efficiency. In addition, through fully automatic positioning, the fully automatic bending center can achieve high-efficiency bending efficiency of 0.2s/cut continuous bending.

3. High Security and Easy Operation of Automatic Panel Bender

Compared with the traditional bending method, the fully automatic bending center does not need to lift the plate in the whole process, avoiding the staff from being injured due to improper operation, and the whole bending process is safer. At the same time, the fully automatic bending center is equipped with a variety of intelligent programs, and the staff can operate without professional skills.