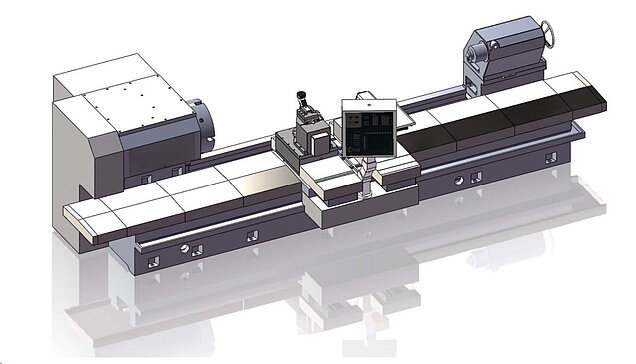

PTRNM-CNC Series

Notching & Marking CNC Turning Machine for Mill-Rolls and Mill Rings - Cresent groove milling CNC Turning Machine for Mill-Rolls and Mill Rings

PTRNM-CNC Specifications

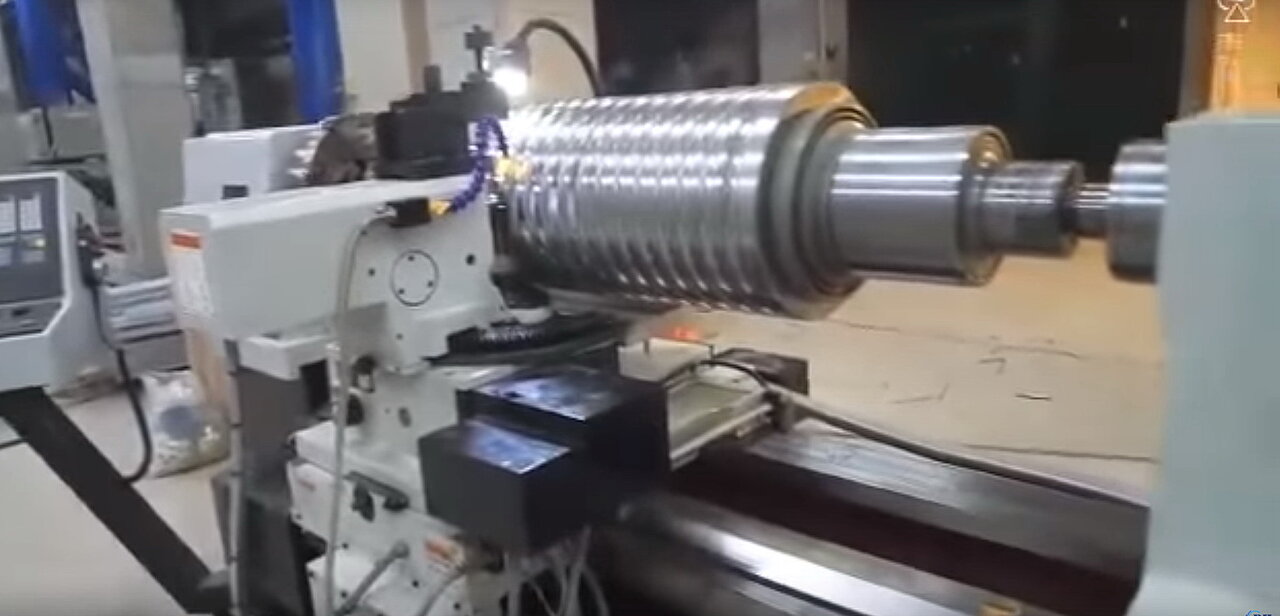

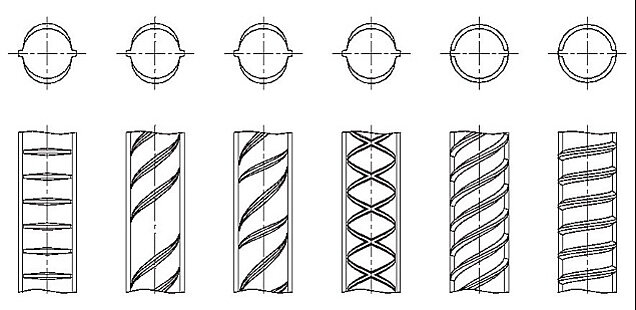

PTRNM-CNC series CNC notching & logo making machine is suitable for processing less than 500/700mm in diameter, the length of the roll is less than 2500 mm, can be automatically processed from 6 ~ 50/60 mm rebar roll of various specifications crescent, the same height rib (completely meet customers’ standard). Machine tool according to customer requirements of automatic cutting different handedness, helix Angle of rib, in roll weeks to any parts or not equal dividing or Spaces; Can automatically on roll at any position of making any kinds of logo you need. Can also according to your requirements for any non-standard roll groove type, text and tag processing. Satisfy a variety of functions and more efficient working you need on this machine .

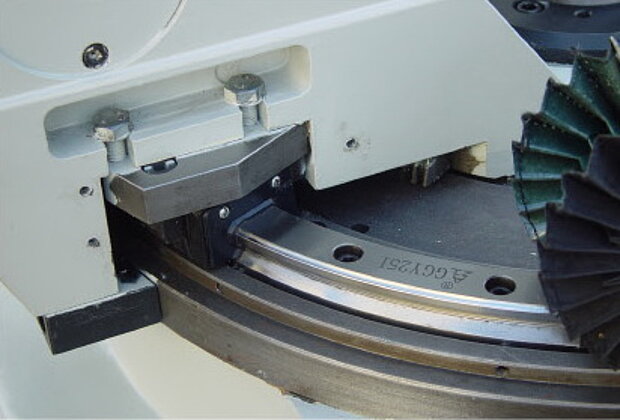

The milling head is supported by the latest rolling circular guide rail, which solves the rigidity problem of the milling head support, and greatly improves the sensitivity and positioning accuracy of the rotation direction. The engraving/milling motor is driven by a high-power 2.2KW motor to ensure the stability in cutting process.

Machine adopts ball screw transmission (avoid gear rack transmission inaccurate faults), the numerical control system, automatic control, to achieve a pass to the next pass automatically move, precise position, without manual movement.

The tailstock of the machine tool adopts the fixed spindle + high-precision tailstock rotation spindle structure, avoiding the problem of insufficient support stiffness caused by the ordinary movable tip.

- In the size range of φ6–φ50mm, reinforced concrete hot-rolled with rib rein-forced steel roll crescent slot, such as high rib groove processing applies to PTNM500-CNC series CNC roll milling machine for the crescent. With a high degree of automation, high processing precision, high cutting efficiency machine is easy to operate, safe and reliable, how labor intensity. More suitable for the processing of tungsten carbide roll rings, high speed steel roll and the composite roll can be milled grooves, engraving machine and so on characteristics.

- The machine bed, headstock main parts such as closed frame structure, high rigidity, good earthquake resistance;

- The machine tool guide by using super audio quenching, good precision.

- The high performance CNC system, can automatically cut the different rotating crescent slot, arbitrary angle;

- Can self action any portions of the indexing or spaces, automatic engraving label designation and grade marking (26 English letters and 0-9 digital engraving)

- Beside the standard Vertical milling head for slots (2.2kw - 0-5000rpm), the machine is also equipped with a Special cutting tool, high speed cutting (2.2 kw 2000-10000rpm). Compared with the traditional processing roll crescent slot, high efficiency.

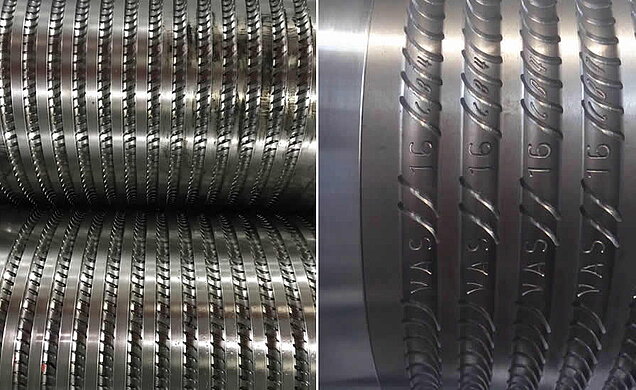

- The quality of the processed roller is high, which can ensure the steel bar reaches the size and precision of the international standard.

CNC ROLLER CRESCENT GROOVES MILLER

Lotey Roll Notching & Branding Machine

Technical Specification of the Notching & Marking Machine

CNC Roller Notching Machine

| PTRNM500-CNC | PTRNM700-CNC | ||

| Maximum roll diameter | mm | Ø500 | Ø700 |

| Minimum roll diameter | mm | Ø100 | Ø100 |

| Maximum roll length | mm | 2500 | 2500 |

| Maximum roll weight | kg | 4000 | 4800 |

| Maximum length of processing roller surface | mm | 1800 | 1800 |

| Work-piece rotation speed | rpm | 0-30 | 0~30 |

| Notching rebar diameter range | mm | 6-50 | 6-60 |

| Tooling spindle speed inclined notches | rpm | 0-600 | 0-600 |

| Notching per roll | as many as required | as many as required | |

| Notching angle | free choise | free choise | |

| Omitting ribs / Enlarging ribs | free choise | free choise | |

| The bed width | mm | 910 | 910 |

| The diameter of chuck (4 jaws) | mm | 400 | 500 |

| The spindle/ Tailstock tape hole | MS5 | ||

| Tailstock guill diameter | mm | 180 | |

| Total size Weight | kg | 6800 | 8900 |

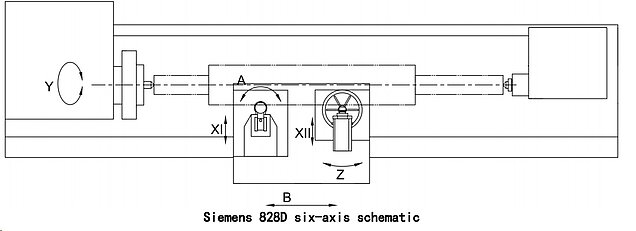

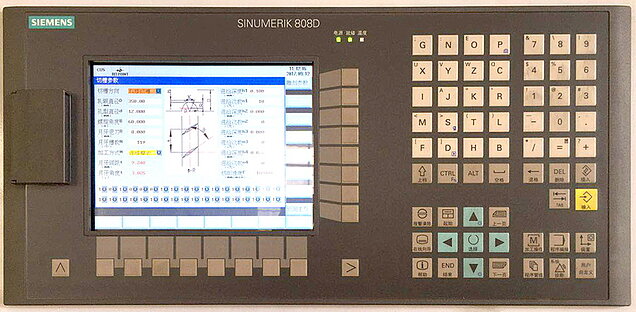

| CNC control | Siemens, Syntec, Mitsubishi or other | Siemens 828, syntec, .. | |

| Working system | 5 axis cnc control | 6 axis cnc control | |

| Work piece Y axis motor | kw | 2.5 | 2.9 |

| Tooling Z axis motor | kw | 2.5 | 2.9 |

| Longitudinal feed (A axis) motor | kw | 1.5 | 4.5 |

| Tooling cross feed spindle (X axis) motor | kw | 1.5 | 2.2 |

| Logo making cutter milling spindle ( variable S spindle axis) | kw | 2.5 | 2.5 |

| Engraving spindle speed | rpm | 24000 | 24.000 |

PTRNM-500/700CNC

CNC MILL-ROLL an MILL-RING NOTCHING & MARKING TURNING MACHINE

Some advantages of the PTRNM-500/700CNC NOTCHING & MARKING TURNING MACHINE for CNC MILL-ROLLS and MILL-RINGS we propose are the following:

• The machine can perform automatically all the international standards and whatever is required in terms of notch skipping and notch enlarging.

• Absolute accuracy for the notch dimensions (rib depth, thickness and angle) and tool positioning is achieved by the special unique direct motor-tool transmission with no belts.

• That’s particularly important when performing tungsten carbide rings and composite rolls. The worker input the diameter of the roller, the rib depth, angle etc. then the CNC will run automatically.

• Tool can move to the next pass automatically; the worker only need input the distance which between the two passes. So, its positioning is a quick, accurate and automatic operation.

• The Y axis and Z axis have zero-point function. The machine can find this zero-point easy. So, in the roll reconditioning operations, the tool can be easily and accurately centered on the worn rib machine can perform automatically all the operations like skipping and enlarging ribs, as well as the change of channel. This means a fantastic reduction in the operator time.

CNC Notching & Marking Machine installed with Siemens

CNC Controller and Siemens Servo Motor, suitable for tungsten carbide roll or high-speed steel roll or high-nickel chromium composited roll or cast-iron roll. It can notch ribs mark the symbol on the roll.

CNC Notching & Marking Machine can be set for following functions:

Function 1: Notching (base function) CNC machine can notch ribs for the deformed steel bar with all standards. CNC machine uses 4 servo motors.

Function 2: Marking (basic function) CNC machine can mark logo, character, drawings etc. on the surface of the roll.