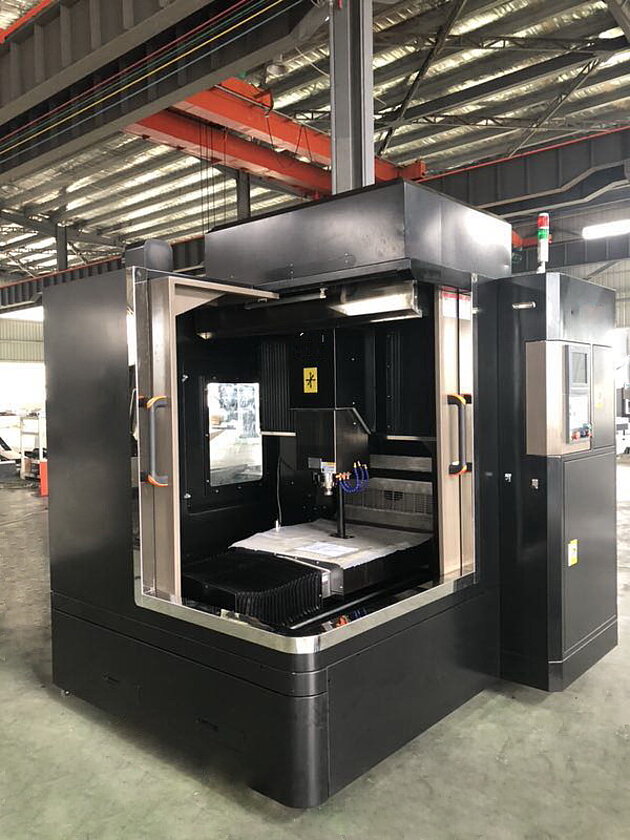

PROFIMACH© HSVMC–III G Series vertical graphite machining center

High precision and flexibility for Electrode, Mold & Die machining

The PROFIMACH© HSVMC–IIIG Series (High Speed Vertical Machining Centers) are designed with a thermal- symmetric bridge type structure to optimize precision and workpiece quality. High accuracy is also enhanced by the constant pre-load high speed spindle.

Walk into any die/mold shop and you’ll find dedicated machines for wet and dry hard milling and graphite milling, three common operations.

Die/mold shops often run dedicated hard milling and EDM machines for these operations because each has special requirements.

Mounting the pressure to minimize costs, while improving machine and spindle utilization will force many machine shops to consider investing in machines with multi-purpose use or so-called all-in-one machines like our HS-VMC Series.

All-in-one vertical machining centers such as our Profimach HS-VMC Series, with graphite and copper milling capability, have wet and dry hard milling capabilities but can also be configured for milling graphite. Using these machines, die/mold shops can lower their costs by reducing downtime, training and maintenance spend. In addition, shops can decrease lead-times and improve machine and spindle usage.

HIGH AFFORDABLE QUALITY HIGH SPEED GRAPHITE MACHINING CENTERS

Profimach HSVMC-G Series

Premium Line Graphite Milling and Engaving Machining Centers

Profimach HSVMC-6050G

Premium Line High Speed Graphite Milling and Engraving Machining Center

Profimach HSVMC-8080G

Premium Line Heavy Duty High speed Graphite Milling Machining Center

We designed our Graphite Machining Centers to not just excel at machining graphite, but also other materials like steel. That means you can rely on them for any task.

Hand scraping Precision

Only the best craftsman can guarantee you this perfect allignement

A bridge type compact vertical machining centre precision-designed to make high-accuracy graphite electrodes and create molds.

Only the highest quality components

Roller type Guideways

Japan/Taiwan high rigidity and heavy-duty roller type linear motion guideways on 3 axis, provide low starting inertia, low friction and high acceleration rates. Servo motors and drives are optimized to ensure immediate &precise machine response necessary in high speed cutting, positioning and contouring.

User-Friendly & Ergonomic guarding design

The design of the guards allows for optimum viewing of the part being machined. Totally enclosed guarding includes roof top/side to keep all the chips, water and noise inside the machine and to have clean, quiet and comfortable environment also around the machine. The machine has been carefully designed to provide a reduction of overall floor space dimensions.

Automatic Tool Changer

Disk Type 12 station automatic tool changer installed as standard.

Optimal structural design

- Main mechanical structures, such as: base, column, saddle, etc., are made of Meehanite casting iron with the process of heat treatment to release the residual stress to ensure every actual miniature movement and to maintain a long-lasting accuracy.

- Box-shaped structural design on beam, together with ladder-like layout of linear guideway makes the combining span of saddle wider and assures a powerful and stable machining capability on the spindle.

- The no-counterweight structural design on headstock is without stagnant phenomenon caused by inertia and no vibration resulted from the counterweight, but with the agile, quick and stable response in feed.

- 3-axis ballscrews, being pre-stretched, can effectively refrain from the thermal deformation and surely guarantee the precise positioning accuracy and repeatability accuracy.

- All components made by casting iron are through special treatment to release internal stress so as to assure good accuracy in long-term operation and long service hours.

Rigid Bridge Column Type Construction

The characteristic twin bridge & column of our HSVMC has been FEM calculated and it’s made of one-piece Meehanite, high quality casting.

This design insures maximum rigidity and performance in High Speed milling and reduces vibrations during heavy cutting operations.

Thermal influences are minimized, due to the short distance between spindle axis and the portal structure.

Thermal analysis of the symmetrical structure proves that this is the optimal

solution for high precision machining of mild products. Full cast iron structure has been stress-relieved giving the machine maximum stability, accuracy and repeatability.

SPECIFICATIONS:

VERTICAL MACHINING CENTRE FOR MACHINING GRAPHITE

| DESCRIPTION | UNIT | HSVMC-6050-IIIG | HSVMC-8080-IIIG |

|---|---|---|---|

| Worktable size | mm | 600*500 | 800*800 |

| Max. X × y × z travels | mm | 600*500*260 | 800*800*400 |

| Gantry width | mm | 650 | 880 |

| Max. Workpiece load | kg | 400 | 400 |

| Spindle to worktable distance | mm | 50-310 | 70-470 |

| Max. Cutter diameter | mm | 20 | 20 |

| Max. Moving speed | m/min | 32 | 32 |

| Max processing speed | m/min | 12 | 12 |

| Spindle motor power | kW | 5,5 | 5,5 |

| Max. Speed of spindle | rpm | 24000 (30000 opt) | 24000(30000 opt) |

| Spindle taper | code | BT 30 (opt ER32) | BT 30 (opt ER32) |

| Spindle diameter | mm | Ø125 | Ø125 |

| ATC tool capacity | pcs | 12 (rotary type) | 12 (rotary type) |

| Positioning accuracy | mm | ±0.005/300 | ±0.005/300 |

| Repeatability | mm | ±0.003 | ±0.003 |

| Overall size | mm | 2440*1910*2500 | 3200*1910*2500 |

| Weight | kg | 4400 | 5820 |

High Speed graphite milling machine

Profimach HSVMC-G Series - Graphite Machining Center

A Clean Shop Environment

The health and welfare of toolmakers that use graphite to make electrodes for use in the electrical discharge machining of molds should be a high priority for management. In addition to the health issues for the workers, the very expensive machinery, such as the EDM machines and milling machines, must be protected from the damaging effects of graphite dust. EDM and injection molding are inseparably linked in the manufacturing process of plastic products.

Anyone who has worked with graphite in the manufacturing of EDM electrodes is keenly aware of the need for proper dust removal during the machining process.

Graphite dust is highly conductive and has been responsible for the damage of many expensive tools and machines. Glass scales can give false measurements due to the settling of dust. Electronic equipment can be short-circuited by the dust as well. The grimy nature of graphite makes it especially annoying if it accumulates on work-benches and desks.

It is in the best interest of everyone to make every effort of maintain a clean and pleasant atmosphere in a mold making or EDM shop. The toolmakers will be happier, the work will be better and the machinery will perform as it should. It is also very impressive to visitors to see a clean, dust-free shop.

Table – Wide cutting Area

The size and load capacity of the table allow the setting up and cutting of larger workpieces of various shapes. Table is 100% fully supported during full stroke of the Y-axis. X-axis is on the bridge.

Automatic tool length measurement standard

Saves precious time and improves your quality

Graphite is a highly abrasive material, and tends to wear out cutters quickly. One of the greatest difficulties encountered when machining graphite is that cutter wear can reach unacceptable levels within the time required to machine a single, multi-featured electrode. As such, to help mitigate the effects of cutter wear, the use of tool measurement probes on the machine tool is highly recommended. Tool length measurement probes, are particularly helpful when it comes to validating the length of cutting tools and tracking their wear state. We have each machine standard equipped with an automatic tool lenght measuring device.

Interior high efficient and economic LED lighting

Saves energy and gives bright and clear interiors

SUPER HIGH SPEED CNC controller

0,4 µsec block processing time - 2500 blocks/second processing speed

Powerful Controller with Mechatrolink M3 Bus Protocol

SYNTEC/Mitsubishi 21/22MA controller comes with serial bus Mechatrolink-III connection motion control, improves machining performance by decreasing interpolation time and increasing surface’s smoothness. Serial bus communication control also improves traditional pulse delay of differentiate transfer time between axis, provides a simpler system and easier to install and setup.

High Speed, High Precision, High Quality

SYNTEC 21/22MA controller is equipped with 2500blocks/sec. computational ability, 2000 block look ahead function and High Speed - High precision feature, such as SPA, HPCC, surface smoother, quick parameter setup, high speed tapping, multiple spindles synchronize motion tapping etc.

SYNTEC 21/22MA is definitively the best solution for high efficiency and high precision mold machining.

High-Speed, High-Precision Machining (HSHP) function

High-Speed, High-Precision Machining (HSHP) function included

The HSHP function (Mode I and mode II) in the dedicated mold making controller can process 2500 blocks/sec (program lines) and look-ahead 2000 blocks each second. These enable smooth motion and enhance surface quality. To advance the precision, the included HSHP function also controls the corner and arc feed-rate efficiently.

Smooth Precision Advanced (SPA) Function

Smooth Precision Advanced (SPA) Function included

Due to limitation of machine condition, servo mismatch can be found even the servo loop gain has been optimized. This error causes dimensional shrinkage especially in high-speed machining. SPA feature is designed to overcome this issue.

Path Smoothing Feature

Path Smoothing Feature included

By trimming the rough program path generated by CAD/CAM software with a tolerance, the desired smooth and fine path is estimated by Path Smoothing function. This improves the surface finish, machining efficiency and stability of machine tool.

High Precision Contour Control (HPCC) function

High Precision Contour Control (HPCC) function included

The tool path generated by CAD/CAM software is generally discontinuous, and it causes negative effects on machining operations. The problems will be more serious because of larger CAD/CAM tolerance. HPCC function fits the discontinuous blocks into a smooth-curve path, and this will enhance the machining precision and reduce the mechanical shock.

Optional high speed 4 and 5 axis milling

With Direct Drive Rotary tables