CNC 12 axis CAMLESS Servo driven Wire Forming Machines

PWF-1225-CNC Series: full 12 Axis CNC Wire forming machine

Wire capacity : 0,4 - 2,5 mm

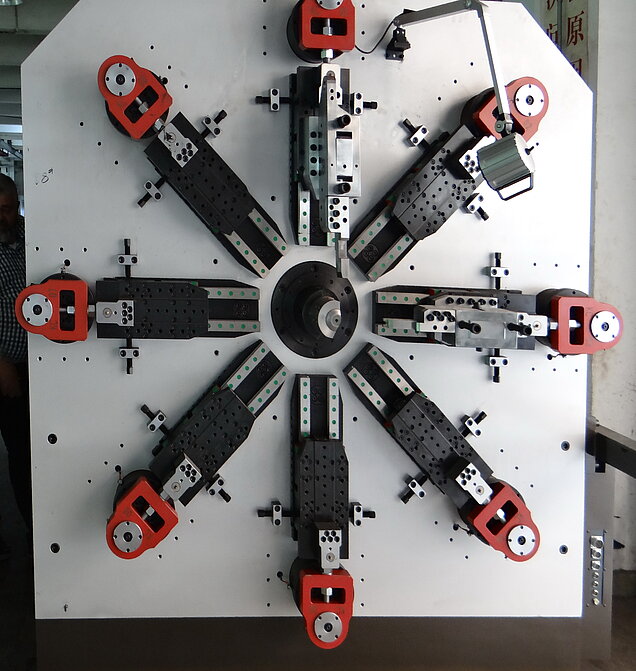

1. PWF-1225-CNC full CNC Wire forming machine, is composed by a high performant Taiwan computer system and with Japan Yaskawa servo motor, special designed with no rocker arm and camless, ,the slide base is separately controlled by eight servo motor, Feeding axis, Quill rotating axis, Wire rotating axis and Spinner axis.

2. It composed of crank connecting link system, feeding and rotating system, coiling straightening system and quill system. It can install the device of hydraulic pressure scissors, low noise; the damage is zero on mandrel and machine. It is suitable for making kinds of tension spring, torsion spring, compression spring, scroll spring, tower spring, flat wire spring and such highly difficult springs. Largely increased the spring making range, it is precise, stable and easy to operate

3. The crank connecting link system are include eight knife rest, eight knife rest are separately driven by eight Yaskawa servo motor through VRB reducer, no influence from each other, make the spring forming handy and easy. Controlled the feeding and wire rotation system synchronous through CNC program, at the same time the feeding accuracy can be reach within 0.1mm during wire rotation.

4.The feeding system is equipped at the rotation system of the machine, it has 3 pairs feeding roller, 2 rollers as one pair, different wire size need different feeding rollers, the computer control the feeding system, the moving unit is 0.01mm, the maximum moving length is 99999.99 unit.

| Number of Axis | 12 |

| Wire Size Range | 0.4~2.5mm |

| Spring Index | 4 |

| Feeding Motor | 1.8kw |

| Quill Motor | 0.75kw |

| Wire Rotation Motor | 2.9kw |

| Forming Motor | 0.4kw*8 |

| Spinner Motor | 0.4kw |

| DImention(L*W*H) | 1600*1120*1740mm |

| Weight | 1800kg |

PWF-1260-CNC Series: full 12 Axis CNC Wire forming machine

Wire capacity : 2,0 - 6,0 mm

1. PWF-1225-CNC full CNC Wire forming machine, is composed by a high performant Taiwan computer system and with Japan Yaskawa servo motor, special designed with no rocker arm and camless, ,the slide base is separately controlled by eight servo motor, Feeding axis, Quill rotating axis, Wire rotating axis and Spinner axis.

2. It composed of crank connecting link system, feeding and rotating system, coiling straightening system and quill system. It can install the device of hydraulic pressure scissors, low noise; the damage is zero on mandrel and machine. It is suitable for making kinds of tension spring, torsion spring, compression spring, scroll spring, tower spring, flat wire spring and such highly difficult springs. Largely increased the spring making range, it is precise, stable and easy to operate

3. The crank connecting link system are include eight knife rest, eight knife rest are separately driven by eight Yaskawa servo motor through VRB reducer, no influence from each other, make the spring forming handy and easy. Controlled the feeding and wire rotation system synchronous through CNC program, at the same time the feeding accuracy can be reach within 0.1mm during wire rotation.

4.The feeding system is equipped at the rotation system of the machine, it has 3 pairs feeding roller, 2 rollers as one pair, different wire size need different feeding rollers, the computer control the feeding system, the moving unit is 0.01mm, the maximum moving length is 99999.99 unit.

| Number of Axis | 12 |

| Wire Size Range | 2.0-6.0 |

| Max Outside Diameter | 120mm |

| Max Feeding Speed | 105m/min |

| Spring Index | 4 |

| Feeding Roller Pairs | 4 Pairs |

| Feeding Motor | 7.5kw |

| Quill Motor | 1.8kw |

| Wire Rotation Motor | 5.5kw |

| Forming Motor | 4.4kw*8 |

| Spinner Motor | 1.8kw |

| DImention(L*W*H) | 3300*1800*2300mm |

| Weight | 8600kg |

PWF-1280WZ CNC Series: full 12 Axis CNC Wire forming machine

Wire capacity : 3,0 - 8,0 mm

1. PWF-1280-CNC full CNC Wire forming machine, is composed by a high performant Taiwan computer system and with Japan Yaskawa servo motor, special designed with no rocker arm and camless, ,the slide base is separately controlled by eight servo motor, Feeding axis, Quill rotating axis, Wire rotating axis and Spinner axis.

2. It composed of crank connecting link system, feeding and rotating system, coiling straightening system and quill system. It can install the device of hydraulic pressure scissors, low noise; the damage is zero on mandrel and machine. It is suitable for making kinds of tension spring, torsion spring, compression spring, scroll spring, tower spring, flat wire spring and such highly difficult springs. Largely increased the spring making range, it is precise, stable and easy to operate

3. The crank connecting link system are include eight knife rest, eight knife rest are separately driven by eight Yaskawa servo motor through VRB reducer, no influence from each other, make the spring forming handy and easy. Controlled the feeding and wire rotation system synchronous through CNC program, at the same time the feeding accuracy can be reach within 0.1mm during wire rotation.

4.The feeding system is equipped at the rotation system of the machine, it has 3 pairs feeding roller, 2 rollers as one pair, different wire size need different feeding rollers, the computer control the feeding system, the moving unit is 0.01mm, the maximum moving length is 99999.99 unit.

Versatile Car Spring Rotating Forming Machine & Spiral Spring Bending Machine

| Number of Axis | 12 |

| Wire Size Range | 3.0-8.0 |

| Max Outside Diameter | 130mm |

| Max Feeding Speed | 100m/min |

| Spring Index | 4 |

| Feeding Roller Pairs | 4 Pairs |

| Feeding Motor | 15.0kw |

| Quill Motor | 1.8kw |

| Wire Rotation Motor | 7.5kw |

| Forming Motor | 4.4kw*8 |

| Spinner Motor | 1.3kw |

| DImention(L*W*H) | 3600*2050*2300mm |

| Weight | 10800kg |