Our CNC Hob Sharpening Machines are developed with Profimach’s extensive experience in cutting tool machining equipment in combination with the latest technology. Featuring advanced computer control, the series of machine are high precision, versatile grinding machines with 4 axes control and 4 axes simultaneous control.

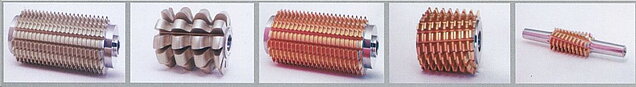

These machines are applicable for sharpening hobs with straight and spiral flutes. In addition, upon customer’s requirement, these machines are available to design with an additional complicated part grinding function for sharpening the cutting edge of the slotting hob.

The models PG-GDX4CNC use an interchangeable grinding wheel shank that helps to reduce wheel change time during machining, resulting in a higher production efficiency and increase of customer’s product development competition capabilities.

As such, Profimach PG-GDX4-CNC series is your best choice in upgrading production competitiveness and product development.

Profimach Hob grinding Machines

Quality but affordable machines

As Gear generation is a quite an aggressive technique, gear cutting Hobs do suffer great wear on the job. Therefore frequent grinding/re-sharpening is mandatory in order to keep up the tool in line with high precision standards.

Profimach machines allow users to grind hobs of all size, module and type with great precision (up to AAA class), reliability and speed.

-

The PG-GDX4CNC-350 machines allow one to grind or sharpen tools up to a job to tail stock distance of 1000 mm. with a maximal diameter of 350 mm and a maximum weight of 200 kg (hob and its supporting device).

-

The PG-GDX4CNC-550 machines are built in order to grind tools up to a job to tail stock length of 1100 mm and can sharpen tools with a maximal diameter of 550 mm an up to a weight of 500 kg, depending on the machine-loading equipment.

Profimach Hob grinders have moreover the best price/performance ratio on the market.

CHARACTERISTICS

CNC 4 axis Hob grinder

Focused on gear manufacturing industries that need to sharpen efficiently their blunt hobs, Profigrind PG-GDX4 CNC Hob Grinding Machine offers a compact design, easy operating solution. Straight and helical hobs can be re-sharpened using either ceramic and CBN grinding wheels

- Straight and helical hobs and milling cutters. Module range 0,5 to 15 and bigger

- Accuracy AAA according to DIN 3968 -from the first.

PG-GDX4 CNC Hob Grinder Series

4 axis CNc hob grinding machines

| Model | PG-GDX4CNC-350 | PG-GDX4CNC-550 |

|---|---|---|

| Max. dia. of work piece | 350mm | 550mm |

| Max. length of work piece | 1000mm | 1100mm |

| Number Flutes of hobs | 1~99 | 1~99 |

| Max. spiral angle | ±20° | ±20° |

| Max. Teeth Pitch (teeth depth) | 40mm | 100mm |

| X-axis Travel | 800mm | 800mm |

| Y-axis Travel | 250mm | 250mm |

| Z-axis Travel | 250mm | 250mm |

| B-axis Travel | ∞° | ∞° |

| Max. feed rate of X/Y/Z axis | 10m/min | 10m/min |

| X/Y/Z axis Motor Output Torque | 8.34Nm | 8.34Nm |

| B-axis Speed | 70RPM | 70RPM |

| B-axis Motor Output Torque | 3.4 Nm | 3.4 Nm |

| Mechanical Grinding Head Speed | 3000/6000RPM | 3000/6000RPM |

| Grinding Head Peak Power | 4/7.5KW | 7.5/11KW |

| Grinding Wheel Size | Φ150-Φ250mm | Φ150-Φ250mm |

| Connection of axis | ISO40/ISO50 | MS4/ISO50 |

| Linear Axis Resolution | 0.001mm | 0.001mm |

| CNC Control System | SIEMENS802D/SYNTEC | SIEMENS802D/SYNTEC |

| Dimension(LxWxH) | 2700x2500x2200mm | 2700x2500x2200mm |