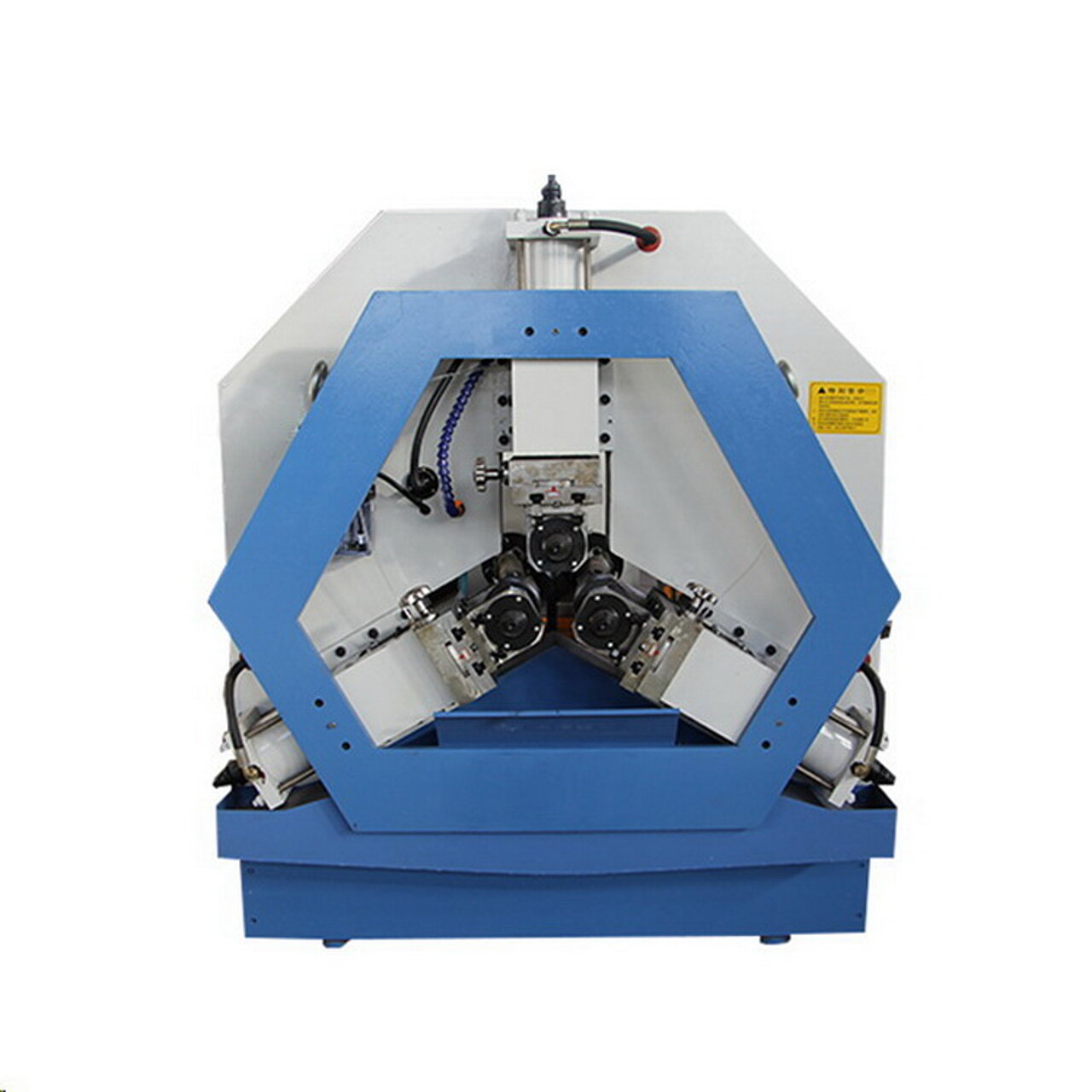

THREE DIES ROLLING Thread Rolling Machine

PTR3-Series

This machine is designed for the thread/profile forming on the thin pipes/tubes, which equipped with 3 same size rolling shafts and needs 3 pieces of rolling dies while rolling. These three shafts are swivel able to ensures optimum capacity and use in making threads and axially parallel profiles in the through-feed process. For this special through-feed process automatic feed of the work is necessary.

This machine can also be used in the in-feed process with parallel die axes, the length of the profile to be rolled depends on the width of the rolling dies, there is no axial movement of the workpiece.

Tapered pipe thread (PT, FT series) forming are most common applications by this machine.

| 3 roll Thread rolling machine | PTR3-40 | PTR3-80 | PTR3-120 |

|---|---|---|---|

| Max roll pressure | 100kN | 200KN | 300KN |

| Max rolling diameter | Φ9-40mm | Φ20-Φ80mm | Φ30-Φ120mm |

| Max diameter of rollers | Φ78-90mm | Φ100-Φ170mm | Φ120-Φ210mm |

| Inner diameter of roller | Φ25.4\Φ35 | Φ54mm | Φ75mm |

| Max thickness of rollers | 20、40mm | 100mm | Φ120mm |

| Axis tilt angle | ±3° | ±6° | ±3° |

| Activities spindle feed rate | 20mm/s | 20mm/s | 20mm/s |

| Workpiece thickness | Less than 2mm | Less than 2mm | Less than 2mm |

| length | unlimited | Unlimited | Unlimited |

| Hydraulic Power | 1.5kw | 4kw | 3.175kw |

| Active Power | 2,2kw | 7.5kw | 11kw-6 |

| Cooling power | 125W | 125w | 125w |

| Total mass | 600kg | 2500kg | 3900kg±50kg |

| Dimensions | 1200×850×1400mm | 1750×1600×1900mm | 2500×1500×2100mm |

THREAD ROLLING PROCESS

Superior quality of thread

Rolling process is recommended when threads are required with superior tensile, shear, and fatigue strength. Other processes like turning, milling and grinding remove material to produce the thread form, but thread rolling displaces the material with hardened steel dies. Rolling dies typically have a hardness between a range of RC 58-63 and there is a specific set of dies for each thread size and each thread form.

-

Static tensile tests on parts formed through thread rolling show overall increases in strength of about 30 percent.

-

Fatigue strength is improved by 50-75 percent.

-

Tests on bolts first heat-treated to a hardness of 35-40 Rockwell C and subsequently rolled show even greater fatigue strength.