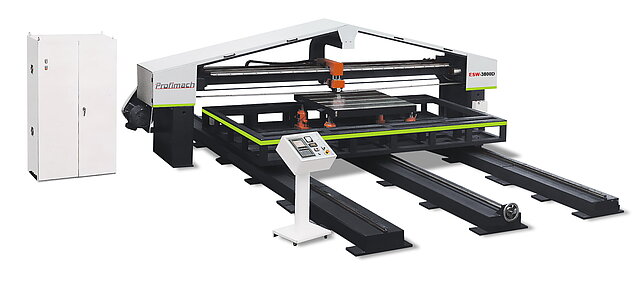

Surface grinding: Portal Twin-Belt Grinding Machine

PRO Steel® Manual - PSTM-II Manual Dual Belt Series

Surface finishing and deburring of big and voluminous parts

PRO Steel® Manual - PSTM-II Manual Dual belt Series, widely used for surface finishing, polishing, and weld bead sanding of formed parts such as boxes, cabinets, and etc. It is the perfect machine to replace manual sanding.

This PSTM-II Manual dual brlt series has two abrasive belt heads parallel to each other. Various type and grit of abrasive belt can be installed for specific applications. It is equipped with double working tables: patented vacuum holder for holding and affixing small enclosures, and the standard working bench for placing large enclosures and cabinets. It is ideal in processing electrical cabinets and enclosures.

PRO Steel® Manual - PSDB-Manual Dual Belt Series

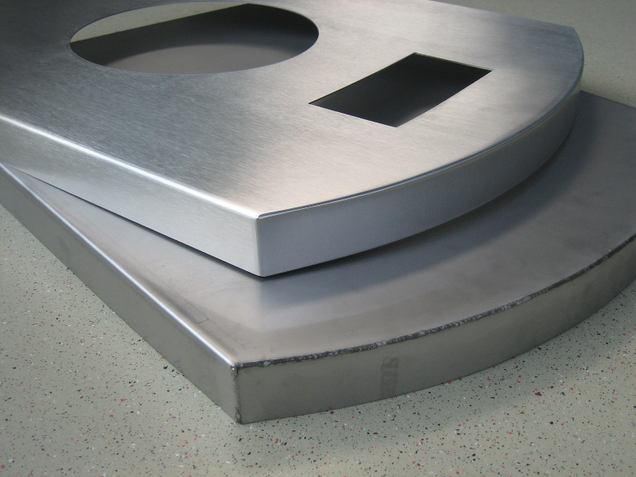

The PortalTwin-Belt Grinding Machine is built for the roughing and finishing on welded edges, corners and surfaces on flat and bulky workpieces out of steel, stainless steel, and aluminum, i.e. cabinets, housings, hoods, furniture parts, frame parts in automotive-, aircraft- and train manufacturing, cylinders , heater, tubes etc.

Dual belt steel surface grinder and sander

Det

PRO Steel® Manual Double Belted abrasive grinding and polishing machine

PSTM - dimensions from 1500 till 9000mm

| Machine model | PSTM-2G-2500 | |

|---|---|---|

| Maximum Work width | mm | 1500 |

| maximum working length | mm | 2500 |

| Maximum working thickness | mm | 600 |

| Size of Belt | mm | 900 x 140 |

| Dimensions | mm | 4350x4200x2350 |

| dust collection capacity | m³/h | 3000 |

| Weight | kg | 3640 |

Advantages of the Twin-Belt Grinding Machine:

- Savings of approx. 50% on working time by use of the 2 separate grinding belts for roughing and finishing: Only one handling and setup of the workpiece

- Further savings of approx. 25% by use of the handling device: The workpiece can be orientated on 5 axes and can be prepared on all sides in one operation

- Manually preparation and pre-grinding on welded seam can be avoided, because the grinding belts can be tensed very smooth and then rotated by 90°. The operator can reach almost all edges and corners of the workpiece and polish the surface

- High ergonomics by free access and view onto the workpiece

- High safety by always accessible E-Stop-String

- Flexible with the Grinding unit - height adjustment

- Simple adjustment of grinding belt speed and pressure for belt tensioning

- Simple control of handling functionality by foot operation panel

- Fast and simple grinding belt changing by self-centering belt run

- Many additional features for safe handling can be adapted or integrated