Two Side High effieciency Deburring and edge rounding Machine

Deburring, deflashing, edge rounding

Solution for two-side-one-pass deburring and edge rounding for metal parts

Focussed on two side deburring and edge rounding

Solution for two-side-one-pass deburring and edge rounding for metal parts

PRO Steel® Two-Side-One-Pass PSGB-Two-Side-One-Pass Series

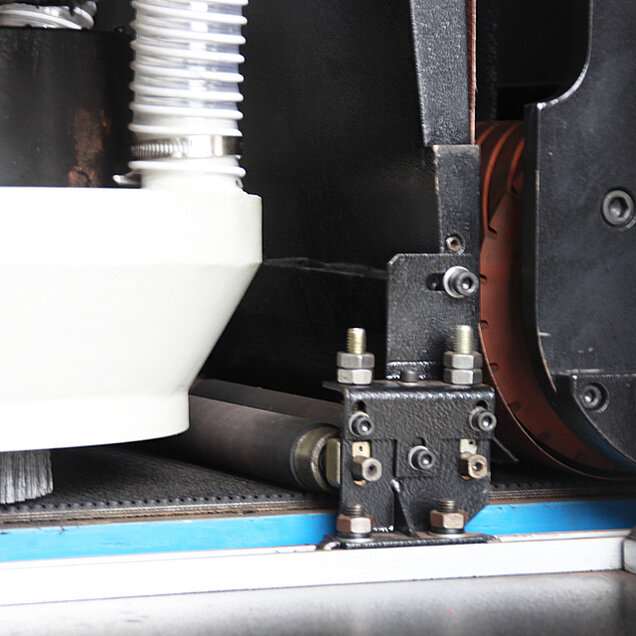

PSGB1300 double-sided deburring machine is mainly for the custom-made machine for medium and heavy plate processing. The combination of abrasive belt and upper burr abrasive belt can completely remove the slag and sintering after laser, plasma and flame cutting, and process it. The edges of the pieces are blunt.

The use of different sizes of abrasive belts and abrasive boxes can achieve different surface effects, solve the cumbersome processing process of manual grinding, provide product quality and stability, high efficiency, low cost, and is anideal choice for medium and heavy plate processing.

-

Dry operation

-

Max. working width: 1280mm

-

Machine opening: 50.8mm

-

2 side 1 pass metal deburring and edge rounding machine

-

Equipped with 1 wide belt head + 1 top and bottom cross belt station

-

Equipped with roller type conveyor

This Machine is suitable for small batch parts deburring and edge rounding. It has much better working efficiency, and more consistent performance than traditional hand held angle grinder or orbital sander. It does a fantastic job on deburring and edge rounding of laser cutting, punching, stamping, and some flat machined parts.

-

This machine utilizes air spring support zero gravity swing arm design. The operator simply needs to grab the handles on the working head, and apply certain pressure on the part to start deburring and edge rounding freely.

-

The working table also has partial vacuum area for accommodating small parts. Simply position the parts on the vacuum area, then the strong downdraft force will firmly hold the parts in place.

-

This deburring machine is equipped with dual abrasive disk and brush configuration which were driven by the same motor. Fast switching between the disk and brush, simply turn 180°, and then lock it. Patented design of quick consumable change of the abrasive disk and brush.

-

It is also capable of processing oversize parts (larger than the working table), as long as it is within the swing arm span.

PSGB1300 Automatic Two-Side-One-Pass Deburring Solution for two-side-one-pass deburring and edge rounding for metal parts. Modules

• G Station (Wide belt): Heavy duty type slag removal, oxide layer removal, surface finishing etc.

• B Station (Deburring block belts): Double sides deburring, edge rounding, oxide layer removal in one pass.

Solution for two-side-one-pass deburring and edge rounding for metal parts

Focussed on two side deburring and edge rounding

Wide abrasive Belt + Top and Bottom Deburring Block Belt

Width: 1280mm