PFR-LVE series

Full Electric Vertical NC precision splines roll forming machines

SPLINE ROLLING MACHINE

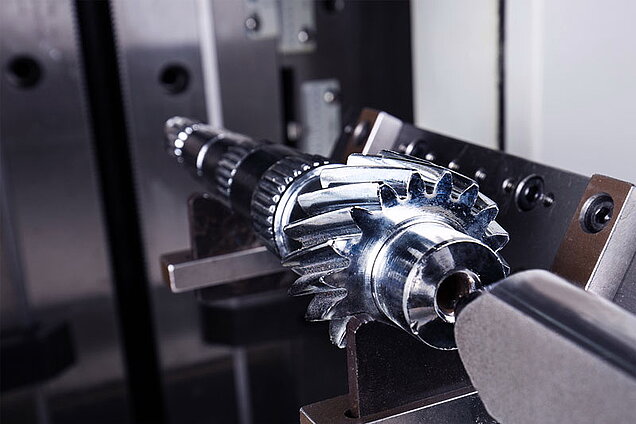

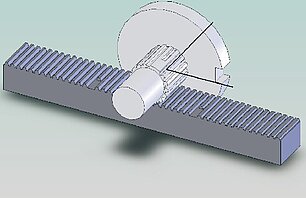

Spline Rolling Machine is using Rack die/cutter instead of Cylinder thread rolling die; many different types of splines, serrations, oil grooves, worm gears, screws, knurls, threads and similar forms can be rolled in individually or in combination in just 3 to 7 seconds.

The Spilne Rolling Machine is inherently accurate, with surface finishes of Ra: 0.05µm to 0.15µm obtainable. Spline Rolling is best suited for long production runs or intermittent runs of a variety of parts. It's the fastest and most economical method of producing involute toothed forms.

Chipless coldforming of involute splines (straight or helical), spiral serrations, oil grooves, and threads

Coldforming – and how it works

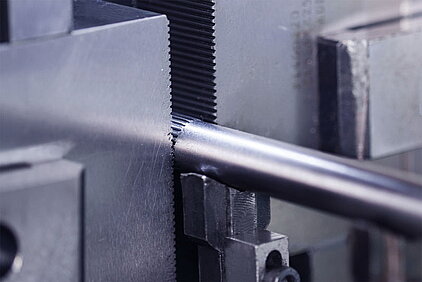

The chipless coldforming of profiles such as involute splines (straight or helical), spiral serrations, oil grooves, and threads only takes seconds with the Profimach coldforming process and is significantly faster than cutting processes. In addition, coldformed workpieces have a higher load capacity and a better surface finish and accuracy. Involute splines and other profiles can be produced very quickly and precisely with this process. The high precision coldforming racks roll and press the required profile into the workpiece during the coldforming process. The material is displaced and flows into the free spaces of the racks. The workpiece is pressed twice during one rotation, i. e. forming takes place in a series of steps. The height of the ground profile in the forming rack increases progressively into the forming area. This causes each rack tooth to press slightly deeper into the material than its predecessor. After reaching the full profile depth, the form gets optimized in geometry and surface finish in the calibration zone

PFR-LVE series - Full Electric Vertical CNC precision splines roll forming machines

PROFILE ROLLING OF SPLINES, RACKS, WORMS AND GEARS

| PFR-LVE Series | 500-LVE | 500-LVWE | 800-LVE | 800-LVWE | 1000-LVWE | |

|---|---|---|---|---|---|---|

| Max module | mm | 1.0 | 1.0 | 1.3 | 1.3 | 1.5 |

| Max out diameter | mm | ⌀20 | ⌀20 | ⌀40 | ⌀40 | ⌀50 |

| Max tool width | mm | 40 | 40 | 80 | 80 | 100 |

| Max work piece length | mm | 400 | 600 | 1000 | 1000 | 1000 |

| Max installing tool width | mm | 90 | 300 | 120 | 300 | 300 |

| The open part diameter | mm | 139.7 | 139.7 | 139.7 | 139.7 | 139.7 |

| Tool size | mm | 20 | 20 | 20/32/38 | 20/32/38 | 20/32/38 |

| Max travel | mm | 500 | 500 | 760 | 760 | 1160 |

| Weight - kg | kg | 3200 | 4200 | 7500 | 9000 | 12000 |

| Lenght x Width | mm | 950x2000 | 1150x2600 | 1420x3000 | 1580x3200 | 1580x3200 |

| Power Drive | type | CNC | CNC | CNC | CNC | CNC |

| E = Electric Drive | ||||||

| W = Wide mold | ||||||

| V = Vertical Dies |

Profimach's spline rolling machines covers the full range of vertical, horizontal, hydraulic drive, servo drive multi-variety spline rolling machines, and has many years of manufacturing and service experience.

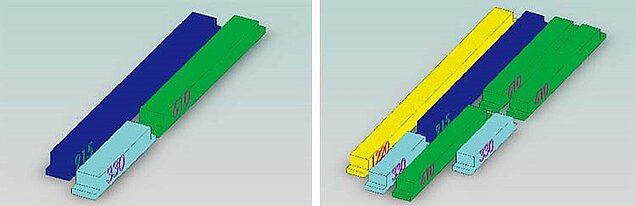

Standard and "wide mold " machines available

Mold Clamping Module

Combined functions of mold clamping module

The accurate mold clamping module makes the mold replacement easy and fast, without the need for tooth alignment.

Variety of combined functions of mold clamping module possible, special "WIDE MOLD" Machines give multi-combined tooling posibilities. You can Roll different surfaces in one time passing

Orientation function of spline rolling

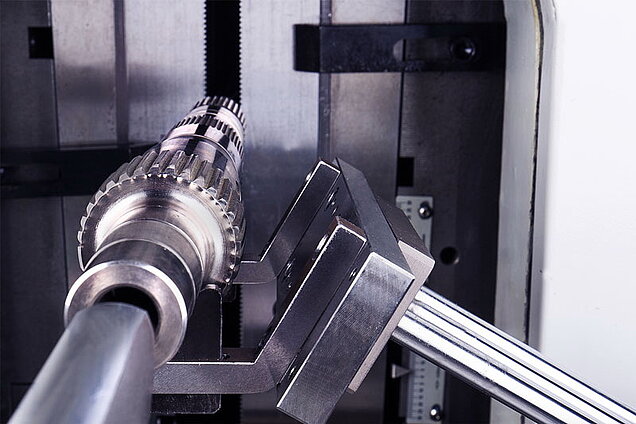

Oriented spline rolling function - incomplete teeth spline rolling function

It has the special function that the workpiece needs to be oriented or has incomplete teeth.

Unique forming principle and precise positioning mechanism can process the spline to the nearest of the shoulder, no need to retract the tool

High benefits of Thread and form rolling process are:

✓ Lower costs

✓ Increased production

✓ Faster lead times

✓ Superior quality and accuracy:

○ Stronger threads

○ Improved finish

○ More accurate profile

Our spline rolling machine can easily replace all following models: FIMAT Hydraulic Spline Rollers – RH800, RH1150 & RH1350, Electromechanical NC Spline Rollers – RM800, RM1150 & RM1350, Roto-FLo Ex-Cell-O Spline Rollers, EX-CELL-O ROTO-FLO 3251S, ANDERSON COOK MARAND 330, ANDERSON COOK MARAND 350S, ESCOFIER INCREMEX 300, EX-CELL-O 3251S, EX-CELL-O ROTO-FLO 3225, EX-CELL-O ROTO-FLO 3251S, EX-CELL-O ROTO-FLO XK-225, GROB ZRM 12 NC-DR-A890, MICHIGAN ROTOFLOW 3237, NACHI PFM 915 FSAL, ROTO-FLO 3251, Cold Rolling Machine - EX-CELL-O - ROTOFLO XK337, Spline roller - Cold rolling, EX CELL O XK 275 CNC, EX CELL O XK251, Ex cell O roto flo XK 225 rolling machine, EX CELL O - XK851 CNC, EX CELL O - XK851 CNC, EX CELL O - XK851 CNC, Machine à rouler les cannelures - FIMAT RL 1350, Rouleuse de cannelures - ESCOFIER INC 300, EX-CELL-O COLD SPLINE ROLLING MACHINE XK 351 OR ROTO FLO 3251, profiroll, profiroll pr400hp, profiroll pr, profiroll pr15hp, ekin, mag series, mag XK 225, mag XK 237, mag XK 251, mag XK 275, mag XK 637, mag XK 651, mag XK 675, mag XK 837, mag XK 851,mag XK 875, ROTO-FLO machines, ROTO-FLO XK225, ROTO-FLO XK237, ROTO-FLO XK251, ROTO-FLO XK275, OSG EX-CELL-O, osg-mag.