Profimach® PGT-CBPG Series

Carbide Blanks production redefined! Expand your expectations with revolutionary and affordable innovation.

Carbide blanks pre-grinding:

Saving money and time and boost your other grinding production.

Profimach® PGT-CBPG Series. This new range of premium Carbide Blank Profile Grinder sets standards in his category. Its values are simplicity, modernity, innovation and robustness allied with a never seen price/performance ratio.

The perfect harmonization of both machining performances and stability is the fruit of innovation efforts based on the long experience of our engineers. The result is reliable high precision production equipment with an irreproachable operation in any situation.

The generous standard equipment underlines the versatility of this concept of the latest generation.

Today this new machine opens the horizon to new performances and quality levels within your daily production of Carbide Blanks at an affordable price.

Save Time, Cut Costs and Increase Productivity:

Economical and affordable Carbide Blanks & Carbide Preforms grinding Machine

Our preform pregrinding expertise allows for major portions of carbide to be removed before it enters your expensive toolgrinder. Compared to the "all in one job done" strategy by doing all the job on your expensive grinder, hard state, drilling of coolant holes, prefluting, and grinding different diameters happens in a fraction of the cost you have now. We leave a minimal amount of grind stock which saves you grinding wheel life, and increases machine capacity. All of these features save you money. Blanks Pre-grinding include:

|

|

Today this new machine opens the horizon to new performances and quality levels within your daily production of Carbide Blanks at an affordable price.

Super high quality Swiss collets guarantee your precision

| DESCRIPTION | UNIT | PGT-CBPG-Series |

|---|---|---|

| Max. X travel | mm | 300 |

| Max. Z travel | mm | 300 |

| Max. Clamping | W20, W25, B32 collet | |

| Max. Moving speed X-Z | m/min | 6 |

| Min. feeding unit | mm | 0.001 |

| Spindle motor power | kW | 5,5 |

| Max. Speed of spindle | rpm | 0-3440 |

| Wheel OD size | mm | Ø100, Ø125, Ø150, Ø 200 |

| Wheel ID Size | mm | Ø20, Ø25.4, Ø31.75 |

| Dimension | mm | 2100 x 2380 x 1950 |

| Weight | kg | 2680 |

Optional Parts measuring probe

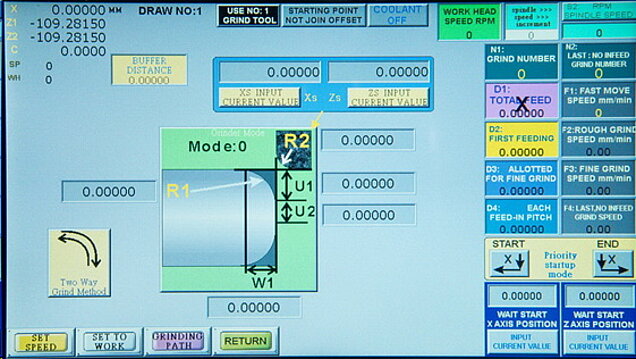

HIGH SPEED CONVERSATIONAL MENU DRIVEN NC CONTROLLER

SIMPLIFIED MENU CONTROL WITH CONVERSATIONAL INPUT